Chris came into school with me to document this neat place and the lengthy process involved in using the printing press.

Find a lead for the length of your line.

I'm setting type for my colophon, which is essentially the end credits.

Back for more leads to go in between the lines.

Setting type

I have added spaces to the ends of the lines but there are still gaps, so I'm adding thin brass and copper pieces to make it tight.

I put those lines on my galley and go back to set more lines using a different type.

Once that's done, I move all the type to my galley.

It's time to make a proof.

I use wooden blocks called furniture to hold my type up and magnets to keep them from moving.

Get some fresh ink

and ink up the type.

Ready to roll it through the proofing press

Lay on three sheets of newsprint

Roll it through

Check for mistakes

That s looks a little weak.

Wipe the ink off the type, pull out the offending letters, replace them with ones that are hopefully better.

Re ink

Ready to go again

This is the fun part.

Much better!

Now, that is not exactly how Joan said it. I have a linoleum block for that part. What I'm trying to do is get all my type proofed. Since these are all separate lines, it will be easy for me to separate them out on the press.

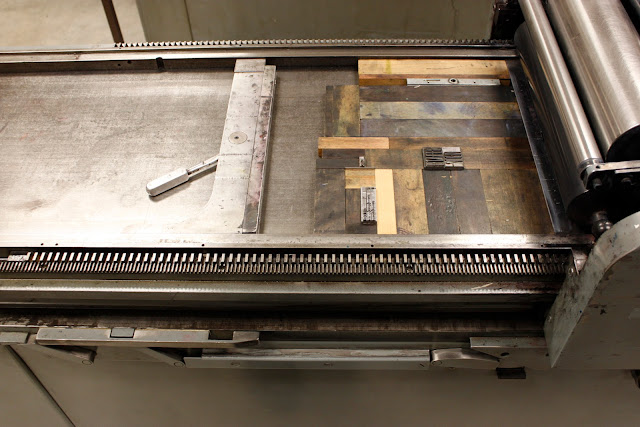

I move my type onto the press (carefully) and start measuring out what size furniture I need to fill the gaps. The furniture comes in lengths of 10, 15, 20, 25, 30, 40, 50 and 60. The widths come in 2, 3, 4, 5, 6, 8, and 10, so you'd better get your math skills ready. Oh, and we're measuring in points and pikas.

It is a time consuming process.

This is basically what it looks like: me running back and forth with furniture.

Now I can add the quoin (coin), which is a metal expanding piece.

I use a removable key to crank the quoin open and push against the furniture.

Tighten the bottom and make sure none of the type can wiggle.

Ink the press

Set the rollers down and turn on the press.

Chris took a ton of pictures. I like these because you can see the ink spread onto the rollers.

Let's hope that last video made it.

No comments:

Post a Comment